Technology

Our technological breakthrough is a result of years of R&D by an industrial consortium, with research grants from the Austrian state/EU, which perfected a new advanced form of proven torrefaction technology we call NextFuel Torrefaction Technology. A unique feature of this technology is the built-in heat exchange element which have a very positive influence on scalability.

Until now the biomass sector has mainly focused on wood as raw material, producing low density wood pellets and (to some extent) wood-based bio-coal from residues and pulpwood. Due to the limited amount of raw material available it has proven impossible to produce enough volume to cost-effectively, and at sufficient scale, replace coal and other types of fossil fuels.

NextFuel AB has succeeded in getting torrefaction to work reliably on a huge variety of biomass raw material in addition to wood, including fast-growing, abundant, carbon rich plants like elephant grass and bagasse (waste from sugarcane), and have reached a production capacity of 8 tonnes per hour per production line.

This new raw material flexibility enable us to scale up fast, and it also gives our clients access to a nearly infinite amount of abundant and fast growing raw material. The briquettes can be produced with consistent high quality and energy density (22-28 GJ per tonne), and we are able to produce at a cost that enable this clean fuel to compete with fossil fuels in terms of prices most places in the world.

By growing plants with a carbon cycle of only a few months, our clients have the possibility to almost immediately capture enough CO2 from the atmosphere to contribute to reverse global warming. All because of a both natural and profitable form of biological carbon capture.

The technology is proven, and fully tested, at our factory in Austria, and is now ready for commercial market roll-out. NextFuel and local partners are currently implementing the first phase of several commercial projects, starting with large scale commercial projects in Europe, America and Africa. Going forward, we will begin licensing our technology to companies all around the world.

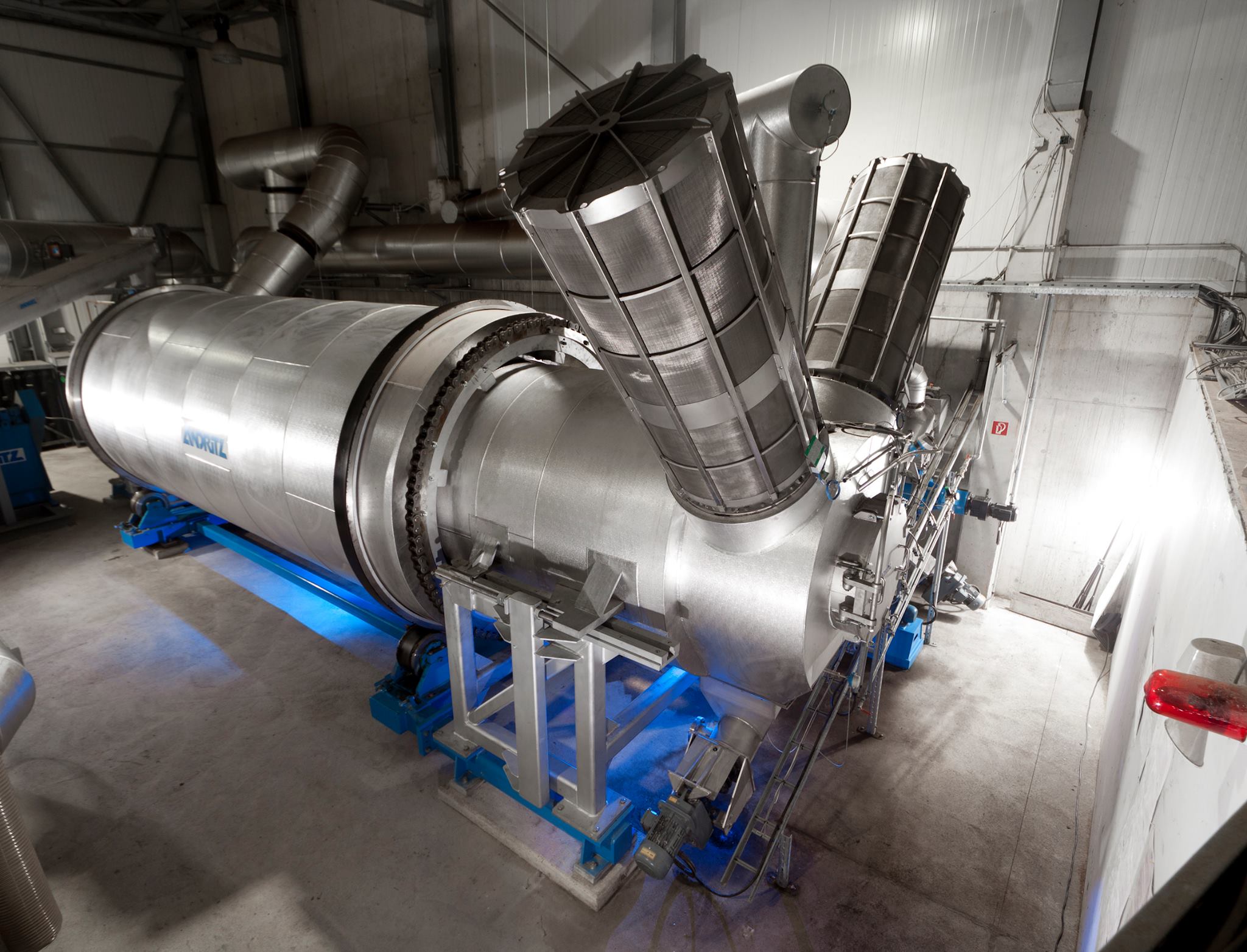

Our unique and patented NextFuel™ torrefaction reactor, based on the rotary drum principle, provides a unique flexibility when it comes to its biomass raw material input. It will reliably process both energy crops like different kinds of elephant grass, agricultural waste like bagasse and paddy straw, and forestry waste like wood residues and low quality wood. This flexibility enables fast scaling at lower cost, and additionally provides the projects an opportunity for better carbon footprints. With some of these projects (e.g. elephant grass), the net amount of CO2 in the atmosphere can even be reduced, making NextFuel™ briquettes the world’s first commercially viable carbon negative fuel.

Below are some of the crops that we and our clients can use to produce NextFuel™ briquettes:

Elephant grass (Miscanthus x giganteus, Pennisetum Purpureum or napier grass, hybrids like bana grass and king grass) is a unique type of specialized perennial grass that can grow 4 to 7 meters in only 100 days, and produce many times the amount of biomass that natural or plantation forests do per hectare per year, with easier harvesting as well. So elephant grass differs from traditional wood biomass that needs decades to grow and requires a much larger land area to produce the same biomass yield.

Although uneconomical soil types and climates do exist, also for elephant grass production, elephant grass can nevertheless grow very well on marginal land – a report from China shows an average drop in yield of only 12.6% for the country’s total marginal land areas (compared to the average for total arable land), and a report from Europe shows a drop of maximum 11% for 99% of the continent’s saline soils. A report on eroded soils in Missouri, USA (marginal for grain crops) showed high yields for miscanthus. The EU project MAGIC estimates that there is 449 901 km2 of marginal land suitable for Miscanthus x giganteus plantations in the European Union. This is an area as large as Sweden. According to IRENA (International Renewable Energy Agency), 1.5 billion hectares of land is currently used for food production globally, while "[...] about 1.4 billion ha [hectares] additional land is suitable but unused to date and thus could be allocated for bioenergy supply in the future." Expected yields for Miscanthus x giganteus range from below 20 to 40 dry tonnes per hectare per year. For comparison, the IPCC writes that the average net growth for natural forests in Europe is 2.3 dry tonnes per hectare per year (harvest-related losses are not subtracted.) In the tropics, yield expectations are generally higher.

Marginal land is much cheaper to lease than arable land, since it is not suitable for food production. Approximately 20% of the total amount of CO2 the grass captures from the atmosphere while growing, remains in the soil (in the form of carbon.)

When the fuel is burned, it releases CO2 that was captured from the atmosphere only a few months ago. Not millions of years ago like with fossil fuels, or decades ago like with wood pellets. The net CO2 contribution to the atmosphere is therefore zero. Additionally, for each completed cycle of burning and growing, less and less CO2 will reside in the atmosphere, because more and more is deposited in the soil. If the amount of stored carbon more than compensate for the amount of carbon emitted during harvesting, processing and transport, the fuel becomes carbon negative. Several research teams have concluded that elephant grass fuels can be carbon negative.

In the long run elephant grass can potentially store so much carbon in the soil that even marginal lands become fertile. According to FAO (Food and Agriculture Organization of the United Nations), soil carbon «[…] provides nutrients to plants and improves water availability, both of which enhance soil fertility and ultimately improve food productivity.»

So a big difference from other types of biomass and biofuel is that NextFuel™ briquette production in the long run potentially can contribute to increasing the world’s food production instead of decreasing it. Additionally, it might help reduce desertification of marginal lands. Also, according to a report from the EU-funded miscanthus research project OPTIMISC, «[…] miscanthus stands are usually reported to support farm biodiversity.» Researchers also argue that miscanthus farming leads to significantly improved water and soil quality, and that it has a very large global cooling effect since the fields stay green for an unusually long time during the year (the “albedo” effect; lighter colors reflect more heat than darker colors.)

NextFuel AB gives clients the ability to create new jobs by growing elephant grass on plantations around the world, with a special potential in developing countries. With a NextFuel™ production plant nearby, electricity and heat can be supplied to local industry, and NextFuel™ briquettes can be transported to coal users everywhere.

Another raw material that can be used for NextFuel™ briquette production is bagasse from sugar cane. Sugar cane is the number one agricultural crop in the world, and is also a fast-growing plant with extremely efficient CO2 capture similar to elephant grass. Bagasse is the residue that remains after sugarcane stalks are crushed to extract their juice. NextFuel™ torrefaction reactors can use bagasse as raw material, typically at a very low cost.

Much of the bagasse in the world is burned or landfilled. By using this byproduct to produce clean NextFuel™ briquettes instead, we turn waste into a valuable product that replaces fossil fuels. Several sugar producers have already approached us, as they see our solution both as potentially profitable and as a climate friendly extension of their business chain.

Wood waste/residues can also be used as raw material in the NextFuel™ torrefaction reactor. Because our torrefied briquettes have a higher energy content compared to traditional wood pellets (22-28 GJ/t vs 17 GJ/t), and because our processing is unusually energy efficient, a cost efficient production is achievable in many locations around the world. For instance in our first European project, where our clients plan to start by using surplus wood residues to produce our clean coal copy, on the basis of a CO2 neutral carbon cycle.

It is also possible to use wood from trashed furniture as raw material for NextFuel™ briquettes, thereby realizing more of the potential of the circular economy. EU’s Joint Research Centre writes that «[…] prioritising residues and the circular use of wood remains key for maximising the positive climate impact of wood-based bioenergy.»

The NextFuel™ torrefaction reactor’s high flexibility in terms of biomass input also makes it easier to use a multitude of crops in future projects. Paddy straw, wheat straw, maize stover, bamboo and empty fruit bunch are all possible raw materials for NextFuel™ briquette production in the future, making large production volumes possible for a very low raw material cost most places in the world.

Our clients also have the opportunity to grow elephant grass as a supplement to local crops if needed, or harvest the different types of invasive plants that constitute real problems in many locations worldwide.

If you have any local agriculture raw material residual you would like us to test, just reach out.

After a crop is harvested and dried, it is fed into our revolutionary, patented NextFuel™ torrefaction reactor. Torrefaction is a fuel upgrading technique that makes raw biomass more practical to handle, by making it water resistant, easy to grind, non-corrosive, and energy dense. A unique feature of our torrefaction technology is the built in heat exchange element which have a very positive influence on scalability.

The production process is mainly powered by surplus energy in the raw material itself, and takes a little less than 30 minutes. Specifically, the reactor drives off the off-gases inherent in the raw material, which is subsequently used to produce the heat that is needed for processing.

After the processing is done, the new fuel is cooled and cut into briquettes. The briquettes are now ready to be used directly as a drop-in fuel in coal plants and in many different industries, e.g. in cement and steel production.

The new NextFuel™ briquette has close to the same energy density as black coal and can be used as a clean, direct coal substitute. Because it is clean, with either a CO2 neutral or a CO2 negative carbon cycle (depending on raw material and local conditions), it enables our clients to achieve very large CO2 savings.

The NextFuel™ briquette is the perfect choice for both heating and clean electricity production, in an infrastructure that is based on burning dirty fossil fuels. For instance, a coal plant can continue to operate by swapping some or all of its coal with our clean NextFuel™ briquette, without having to do any expensive rebuilding of the plant. This drastically and economically reduces the carbon footprint and makes it possible to phase out coal fast, while keeping the existing workforce. The plant can stay open, also in the long run, and given the right local project conditions (elephant grass as raw material), actually end up with a carbon negative carbon cycle.

By utilizing the Fischer-Tropsch process NextFuel™ briquettes can also be converted to liquid Sustainable Aviation Fuel (SAF).

A switch to NextFuel™ gives the world a new, fast and inexpensive way to reach the climate targets of the Paris agreement, all without hurting economic growth.